Liquid level gauges are important instruments used in boilers to monitor the level of liquid and ensure the safe and efficient operation of the system. There are several types of liquid level gauges used in boilers, including glass tube level gauges, dual-color quartz tube level gauges, and magnetic flap level gauges.

The magnetic flap liquid level gauge uses a bypass pipe to connect the tank or container equipment, ensuring that the liquid levels of both are at the same height. As the liquid level rises or falls, the float inside the gauge moves accordingly, and the permanent magnet in the float drives the red and white flipping beads to flip 180 degrees via magnetic coupling. This action causes the red and white dividing line on the gauge's scale to indicate the liquid level accurately and intuitively.

Our company's remote transmitter or magnetic switch can accurately and stably output electrical signals, allowing for long-distance display and control.

-

The unique inner flanging process ensures that the main pipe has no welding marks and that the inner wall is smooth with no sharp edges or dead corners, completely preventing the float from getting stuck when floating.

-

The anodized aluminum alloy panel has a more beautiful appearance and is corrosion-resistant and durable.

-

The high-temperature turning beads are sintered with precision ceramics and will never fade.

-

The ordinary remote transmission adopts imported magnetic spring components, which provide stable and reliable performance.

Working Principles of Liquid Level Gauges

Glass tube level gauges use a transparent tube that is mounted vertically along the side of the boiler. The liquid level inside the tube indicates the liquid level in the boiler. The level can be read visually by observing the position of the liquid in the tube. Dual-color quartz tube level gauges use two quartz tubes that are mounted vertically and filled with two different colored liquids. The color boundary between the two liquids indicates the liquid level in the boiler. Magnetic flap level gauges use a magnetic float that is attached to a flap. The flap rotates as the float rises and falls with the liquid level. The position of the flap indicates the liquid level in the boiler.

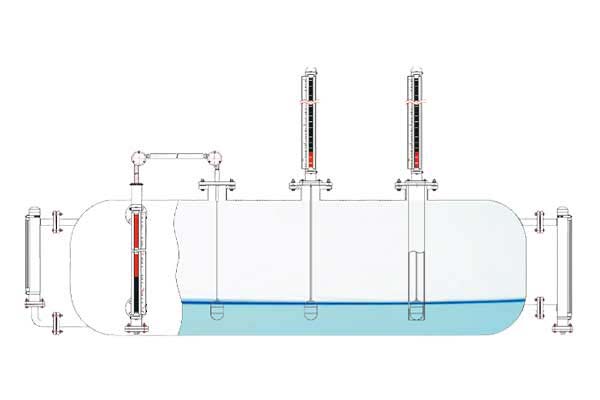

Installation diagram

Applications of Liquid Level Gauges

Liquid level gauges are used in boilers to monitor the level of liquid, such as water or steam, to ensure safe and efficient operation. They can also be used to detect leaks or other malfunctions in the system. In addition, liquid level gauges are used in a variety of other industries, such as chemical processing, oil and gas, and water treatment.

Classification of Liquid Level Gauges

Liquid level gauges can be classified into several categories based on their working principles and designs. In addition to the glass tube, dual-color quartz tube, and magnetic flap level gauges mentioned above, other types of liquid level gauges include sight glass level gauges, reflex level gauges, and transparent level gauges. Sight glass level gauges are similar to glass tube level gauges but are mounted horizontally. Reflex level gauges use prisms to reflect light at the boundary between the liquid and vapor phases, which makes the liquid level easier to read. Transparent level gauges use a transparent chamber filled with a liquid that is in contact with the liquid in the boiler, allowing for direct observation of the liquid level.

Liquid level gauges are essential instruments used in boilers to ensure safe and efficient operation. The choice of liquid level gauge depends on the specific application, and different types of gauges have different advantages and limitations. By understanding the working principles, applications, and classification of liquid level gauges, we can make informed decisions about which type of gauge to use for a given situation.

Characteristics:

-

Two-wire current loop, with isolation between the measurement system and the current loop.

-

Accurate and continuous measurement and control of liquid level under all working conditions (boiler start, stop, sewage discharge, accident conditions, etc.).

-

Tomographic scanning technology compensates accurately for changes in the dielectric constant of the liquid phase medium, changes in the dielectric constant of the vapor phase medium, and temperature changes, without the need for re-calibration under any circumstances.

-

High precision and stability, with a resolution of 0.01mm and an annual drift of no more than 0.5mm.

-

Good electromagnetic compatibility characteristics certified by CE.

-

High temperature resistance, high pressure, and long life.

-

No false water level measurement.

-

The operating software is available in multiple languages including Chinese, English, Arabic, Spanish, French, and Russian, and comes with self-diagnostic function.