Features:

-

Provide a range of copper and steel nozzles for standard burner systems. We offer a series of dedicated nozzles adapted to work area, media, and emission requirements to meet the needs of different markets.

-

The OD series nozzles are designed for civil and commercial high-pressure fuel burner systems and can use light oil and heavy oil (both of which belong to diesel). There are four different injection angles and three different injection patterns.

-

The flow rate of the standard series nozzles ranges from 0.30 to 35 US gallons/hour (the flow rate is under the standard pressure of 100 psi, and the flow rate will change as the pressure changes).

-

Light oil or heavy oil can be used, and they are 100% factory tested.

Performance:

-

basic functions:

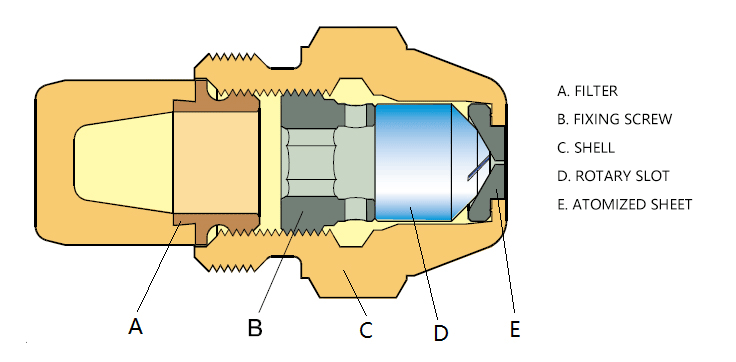

The basic function of a nozzle is to atomize fuel into small droplets and distribute them in a certain spray angle on the cross-section. Atomizing fuel requires energy, which is typically provided by a gear pump driven by a motor in the combustor. The pressure energy cannot directly break up the fuel, but must be converted into kinetic energy through tangential slots in the nozzle, and the fuel is ejected from the nozzle at high speed, rushing into a swirl chamber to form a rotating flow. An outlet hole is located at the center of the swirl chamber, which obtains a certain rotational speed. If the rotational speed is high, a cavity will form at the center of the swirl chamber.

Another function of the nozzle is to meter the fuel. By maintaining a fixed pressure in front of the nozzle, a fixed amount of fuel will be injected. Therefore, to meet the heating needs of different loads, nozzles are designed and calibrated according to different flow rates and spray angles, so that each nozzle of a specific specification can provide a certain amount of fuel within a certain pressure range.

Obviously, the flow rate of the nozzle is determined by the geometric shape of the tangential slots and holes. At the same time, the size of the nozzle also determines the quality of atomization, with smaller sizes resulting in thinner oil films and better atomization effects.

-

main factors that affect nozzle working conditions:

-

Pressure: The higher the pressure, the smaller the droplet size in the atomizer.

-

Relative density: Also known as specific gravity, it is the ratio of the density of a sample of oil to the density of water at the same temperature. Fuels with higher relative densities have a smaller flow rate than those with lower relative densities, but they have a higher energy density, which results in greater power output from the burner.

-

Viscosity: Within a certain range of viscosity, the flow coefficient of small high-pressure atomizers increases with increasing viscosity. The effect of viscosity on nozzle flow rate also varies depending on the type of nozzle and the pressure. For the same model of nozzle, the effect of viscosity is less pronounced for larger-diameter nozzles than for smaller-diameter ones. The higher the pressure, the less effect viscosity has on the nozzle.

-

Temperature: The rate of formation of gels and precipitates generated by fuel increases with temperature. When the fuel is at rest, the nozzle temperature is highest, which further promotes the formation of gels and precipitates. After several openings and closings of the burner, the colloids accumulate in the nozzle, affecting the flow rate and atomization shape of the nozzle. Additionally, deposits in the nozzle slot may cause blockage, especially in small nozzles.

-

Surface tension: Surface tension is the tendency of a liquid surface to minimize its surface area. Surface tension resists any external forces that tend to separate or change the shape of the liquid. When the liquid diffuses and forms an atomized body, surface tension plays a role in restoring the leading edge droplets of the liquid film.

-

Boiling point: Fuels with higher boiling points produce flames that last longer when burned. If the boiling point of the fuel is very high, the carbon particles in the flame will pass through the combustion zone without fusing with the flame. In this case, it is difficult to remove the flame without a large excess of air.

-

factors affecting nozzle atomization quality

The nozzle is one of the key equipment that affects the combustion performance of the oil burner. The quality of nozzle design and manufacture will directly determine whether the ideal atomization quality can be obtained, and reasonable use can ensure high-efficiency and low-noise combustion.

The main indicator that affects the atomization quality of the nozzle is the droplet size. The smaller the droplet size, the easier it is to achieve efficient and complete combustion.

For nozzles, under the same pressure, the smaller the nozzle flow rate, the smaller the droplet size; the lower the viscosity of the fuel, the smaller the droplet size; the larger the atomization angle, the smaller the droplet size. Nozzles with a finely machined outlet orifice produce smaller droplet sizes than nozzles with a rougher finish, and increasing fuel pressure before the nozzle reduces droplet size.