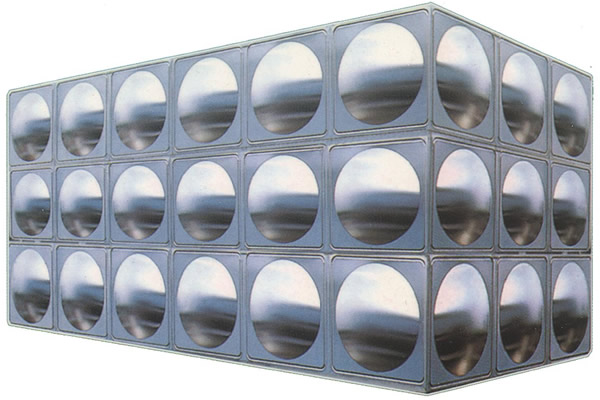

Stainless steel insulation water tank refers to a water tank made of food-grade stainless steel as the inner layer, with insulation material as the core layer, and stainless steel packaging material as the outer layer. The inner and outer stainless steel layers are optimized in combination with the core layer to form a stainless steel water tank.

The stainless steel insulated water tank uses food-grade stainless steel (SUS304) and ER308 welding wire with high corrosion resistance. The water tank is designed with reasonable pressure distribution, low wind load, no dead corners, no sedimentation, and good sealing to completely prevent harmful substances in air dust and small animals from entering, ensuring that the water quality is not affected by secondary pollution.

Insulation Material:

-

The core medium can be made of polyurethane foam, polystyrene, polypropylene, rock wool, PEF.

-

The inner layer can be made of food-grade stainless steel plate, galvanized plate, aluminum plate, or color steel plate.

-

The outer layer can be made of general materials such as stainless steel plate, galvanized plate, aluminum plate, or color steel plate.

Specifications:

The following are the diameters and heights of cylindrical, vertical, flat-bottomed and flat-topped insulated water tanks. The dimensions of horizontal and conical (arc-shaped top) tanks may differ, and the actual product shall prevail.

Insulation Principle:

This insulated water tank is made of stainless steel plate, color steel plate, etc. as the surface layer, and closed-cell flame-retardant self-extinguishing polystyrene material board or polyurethane as the core layer. By optimizing the combination, the internal and external layers jointly achieve the best insulation effect. The water tank has the advantages of beautiful appearance, high mechanical strength, excellent performance, and convenient assembly.

Insulation Time:

The temperature of the insulation material made of polyurethane foam as a whole drops by no more than 4℃ within 24 hours at room temperature. The temperature of the insulation material made of other materials drops by no more than 10℃ within 24 hours.

Structure:

The stainless steel insulated water tank is composed of three parts: the high water tank, the storage water tank, and the low water tank. The high water tank is equipped with a mechanically controlled water replenishment device, a flushing valve, a drain valve, and an electrode float switch. The valve seats of the water replenishment device and flushing valve are respectively connected to the three-way flushing pipe set in the storage water tank. When the drain valve is opened, the high water tank is connected to the storage water tank. The low water tank is equipped with a lever float switch, and when the float valve core is opened, the storage water tank is connected to the low water tank. The low water tank also has a submersible pump, filter, and sewage discharge pipe. The outlet pipe of the submersible pump is located in the high water tank, and the submersible pump is controlled by the electrode float switch in the high water tank. Using this water tank can save a large amount of clean drinking water, and it has significant social and economic benefits. It can be installed and used in boilers systems, hotels, restaurants, enterprises, institutions, and industrial and mining units with large water consumption.

Features:

-

The inner tank of the insulated water tank is made of stainless steel, and the outer tank can be made of stainless steel or aluminum-zinc plating. It is lightweight, beautiful in appearance, and clean and hygienic.

-

The whole tank is insulated with polyurethane foam, which has low heat loss and good insulation effect.

-

The joints are welded by high-frequency resistance seam welding to ensure that they are not easy to rust or leak water.

Production Principle:

An insulated water tank is a type of water tank that uses a thermal insulation material, similar to that used in a thermos, as the core layer. Stainless steel is used as the inner surface layer, and ordinary stainless steel sheet is used as the outer layer. These three materials are combined to form a suitable and excellent combination, forming the basic structure of a stainless steel insulated water tank. Therefore, the insulated water tank consists of three layers: the core layer, inner layer, and outer layer. The insulation material of the core layer can be 50mm or 80mm polyurethane foam, polystyrene, PEF, etc. The inner layer is made of stainless steel, so high-quality SUS304 food-grade stainless steel plates and galvanized sheets are used. Finally, the outer layer is usually made of ordinary stainless steel stamping sheet or flat plate, and can be made of SUS304 or SUS201 stainless steel. The thickness of the water tank plate can be determined according to the size and height of the water tank, and asbestos or rock wool can also be used as insulation materials.

Precautions:

-

The insulated water tank can be installed on a flat roof, on the ground, or in locations such as balconies, kitchens, and bathrooms indoors or outdoors for residential use.

-

The installation location of the insulated water tank should be convenient for drainage, and the hot water tank should be placed as close as possible to the water source and the main unit installation location to reduce heat loss in the pipes.

-

For building projects, regardless of the size of the water tank, it should be placed on load-bearing beams. When water tanks exceeding 5 tons, customers are required to create a load-bearing foundation, which should have a load-bearing capacity greater than twice the weight of the water tank when filled with water. For wide floors or large water tanks, it is recommended that customers divide the water tank into multiple ones and place them on load-bearing beams (in normal circumstances, a single circular water tank should not exceed 10 tons, and a single rectangular water tank should not exceed 20 tons).

-

When placing an insulated water tank on the rooftop, the stainless steel mirror will reflect light, which may affect the surrounding office or living environment.

-

When installing the insulated water tank on the ground, a foundation of at least 150mm in height should be constructed, and the location of the water tank should not affect the surrounding residents.

-

The foundation on which the insulated water tank is placed must be level, and there should be no standing water on the foundation surface. If using welded support brackets made of I-beams or channel steels, the location where the water tank is placed must be covered with a steel plate to create a level surface.

-

Circular insulated water tanks should be placed upright and should not be placed horizontally.

-

There should be a maintenance space of more than 600mm around the water tank.

-

Because the circulation water pump configured with the unit does not have a suction capacity, the installation position of the water tank should not be lower than the unit. Considering the limited lift/pump head, it should not be much higher than the unit either. If conditions permit, it is best to place it at the same level.

Advantages:

-

Energy-saving: The dense and well-insulated polyurethane foam insulation layer ensures good insulation of the water tank. The high-frequency resistance welding of the tank structure and maintenance holes ensures the tightness of the tank, effectively preventing external rainwater and internal water vapor from damaging the insulation layer and reducing heat loss. The anti-thermal bridge design of the tank body, top, and bottom reduces heat loss. The anti-convection device installed on the overflow hole effectively prevents convection heat exchange between the air in the tank and the outside air, reducing heat loss. According to testing by authoritative professional institutions, the temperature drop is less than 3 degrees in 24 hours.

-

Durability: In-depth research on the corrosion mechanism of stainless steel and long-term practice has solved the problem of corrosion. High-quality stainless steel plates are used for integral rolling and pressing, with circular butt joints. The tank top and bottom are formed in one step by a large hydraulic press, ensuring the strength of the tank. High-frequency welding machine welding ensures reliable welding seam quality and eliminates welding stress, significantly enhancing the anti-corrosion performance.

-

Aesthetics: Large specialized equipment is used with strict production processes, necessary fixtures, and standard production, ensuring straight and smooth pipe connections and a smooth and rounded product appearance.

Applications:

-

Residential, commercial, office buildings, residential communities, government agencies, hotels, schools, and other places for domestic and firefighting water.

-

Production and domestic water for industrial and mining enterprises.

-

Water for various types of circulating water, cooling water, and hot water supply systems.

-

Acid and alkali reserves/storage

Installation Schematic Diagram:

-

Manufactured in accordance with standard design drawings 02S101, the tank body is made entirely of professional food-grade SUS-304 stainless steel, which is lightweight, aesthetically pleasing, and hygienic. The joints are welded using high-frequency resistance welding to ensure no rust or water leakage. The sealing performance is excellent, ensuring the water quality and avoiding secondary pollution.

-

The 50mm thick integral polyurethane foam insulation layer is combined with high-speed conductive heat transfer fluid for excellent insulation performance and minimal heat loss. The density of the integral water tank polyurethane insulation layer has been tested to be above 39 degrees, compared to an industry standard of 19 degrees.

-

After long-term testing, the high-speed conductive insulation material can absorb solar energy in summer, raising the temperature of the hot water in the tank. In an environment with a temperature of 20 degrees, the temperature drop is less than 1 degree in 24 hours. In winter, the closed-cell nature of the conductive insulation material reduces heat loss to a minimum. In an environment with a temperature of 5 degrees, the temperature drop is only 2 degrees in 24 hours.

-

The water tank foam insulation layer is supported by a stainless steel mesh-like welded support, and the bottom is reinforced with a cross-shaped groove steel to make the entire water tank more sturdy and stable, preventing deformation.