The horizontal condensation water recycling device is a key equipment to achieve the closed recovery system of steam condensation water, widely used in various fields such as petroleum, chemical industry, electric power, metallurgy, paper mill, textile, rubber, light industry, food, pharmaceuticals, tobacco, coal, hospitals, and hotels. It can conveniently and effectively completely seal and recover the condensed water and its heat energy generated by the steam from indirect heating system, completely solving the cavitation problem of the high-temperature condensation pump. The device also enables the collection and pressurized delivery of high-temperature condensation water. The horizontal condensation water recycling device plays an important role in reducing resource waste and environmental protection.

Necessity and Value of Closed-loop Recovery:

-

The value of condensation water = cost of raw water + cost of softening (desalination) + cost of deoxygenation + heat value.

-

Condensation water has a high temperature, usually above 100℃ in production processes, and its enthalpy value accounts for about 20%-25% of the total enthalpy of new steam.

-

The quality of condensation water is very pure, close to desalinated water after softening or desalination treatment, and almost free of corrosive gases such as dissolved oxygen and carbon dioxide, and there is no corrosion.

Condensation water has a certain residual pressure that can be utilized. In traditional steam heating systems, some of the condensation water is directly discharged, and some are recycled in open tanks or pools, which have certain drawbacks:

-

Open-loop recycling discharges a large amount of secondary flash steam and leaks from steam traps, causing 30%-80% heat loss of condensation water and wasting some water resources, also causing the complete loss of residual pressure resources of condensation water.

-

The emission of secondary flash steam causes environmental thermal pollution and affects the image of the enterprise.

-

Because the condensation water contacts the atmosphere again, it causes secondary oxygen dissolution in the already deoxygenated condensation water, shortening the service life of related equipment and pipelines due to oxygen corrosion, increasing the deoxygenation load, and increasing the deoxygenation cost.

-

In the actual system, normal leakage steam from the steam trap is also discharged, which must be naturally cooled before transportation and utilization, so the volume of the tank is made large enough to facilitate cooling, further wasting energy.

Design Principle:

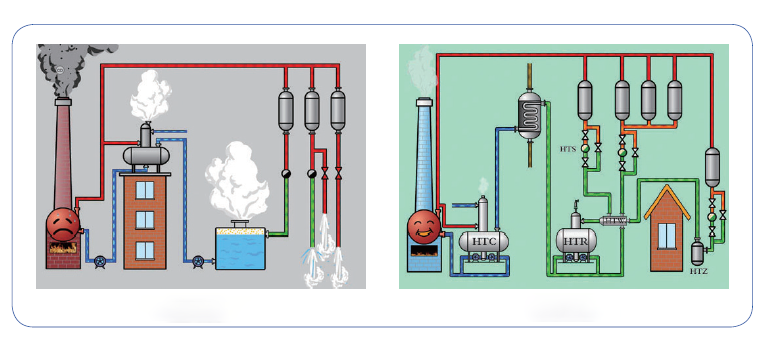

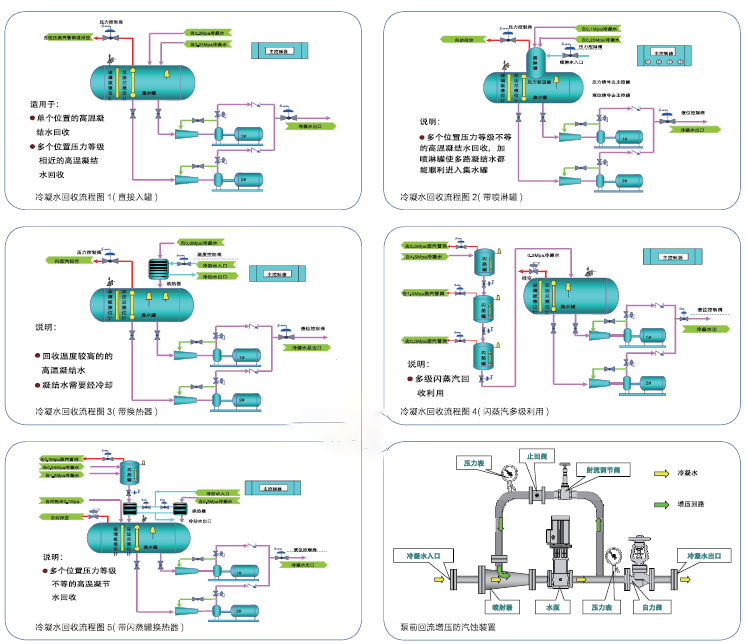

The design of the closed condensation water recycling device follows the basic principles of fluid dynamics, two-phase flow of steam-liquid, and heat transfer. Based on the characteristics of steam-water two-phase flow, the system can completely eliminate the causes of cavitation and air blockage of high-temperature condensation water pumps through unique pressure regulating devices, suction pressure regulating devices, cavitation elimination devices, etc., and achieve completely closed recovery of condensation water and secondary flash steam.

The condensation water recycling device comprehensively considers various functional requirements of the condensation water recovery system. The internal design includes flash vaporization devices, debris removal devices, condensation water guide devices, automatic pressure regulating devices, and cavitation elimination devices, to achieve various functions such as steam-water separation, condensation water filtration, temporary storage and transportation of condensation water. Together with the external configurations of different equipment (steam pressure reduction, circulating jet inlet, condensate water pressurization) and the design of the return pipe system, it realizes the multi-channel network of condensation water with different pressures and achieves the purpose of closed recovery.

Advantages:

-

Energy saving and environmental protection: The fully enclosed recovery system eliminates any emissions of secondary flash steam and drain leakage, and maximizes the recovery of heat energy and water resources in the condensate water. The condensate recovery rate can reach 95%. The device also improves the heating efficiency of equipment, with utilization rates of 10%-25% and fuel savings of 20%-25%.

-

Highly automated: The device uses intelligent automatic control with measures such as automatic pressure adjustment, automatic alarm, and dual pump automatic switching. It forms a closed-loop water recycling automation management system with various functions integrated, ensuring stable and reliable operation, and easy maintenance.

-

Elimination of cavitation: Based on fluid mechanics and the principle of subcooling, combined with the dynamic characteristics of steam-water two-phase flow, the device adopts a series of advanced cavitation elimination technologies, completely eliminating the problem of cavitation in the condensate water pressurization pump and ensuring that the water pump operates in the optimal state for transporting single-phase high-temperature liquids.

-

Reduction of corrosion, extended lifespan: After being recovered in a closed system, the condensate water is protected from contamination by dissolved gases such as oxygen and carbon dioxide, eliminating oxygen corrosion and extending the lifespan of equipment and pipelines.

-

Simple structure, reliable operation: The device features a circular water tank structure, integrated mechanical and electrical design, compact structure, small volume, small footprint, easy installation and use.

-

Short payback period, good economic benefits: The device saves energy, water resources, and investment, purifies water quality, extends the lifespan of boilers, water pumps and other equipment, and strengthens boiler output. All investment costs can be recovered within 3 to 12 months after the device is put into operation.